Support: If, after consultation with our technicians, remote access to your system is necessary, please follow the link to download and set up the connection using TeamviewerQS.

We stand for quality, reliability and sustainability

25 years of experience in special machine construction with a focus on the industrial adhesive tape industry and automation solutions with pick-and-place and robot systems. Versatile expertise and a very high vertical range of manufacture enable customer-specific complete solutions from A-Z.

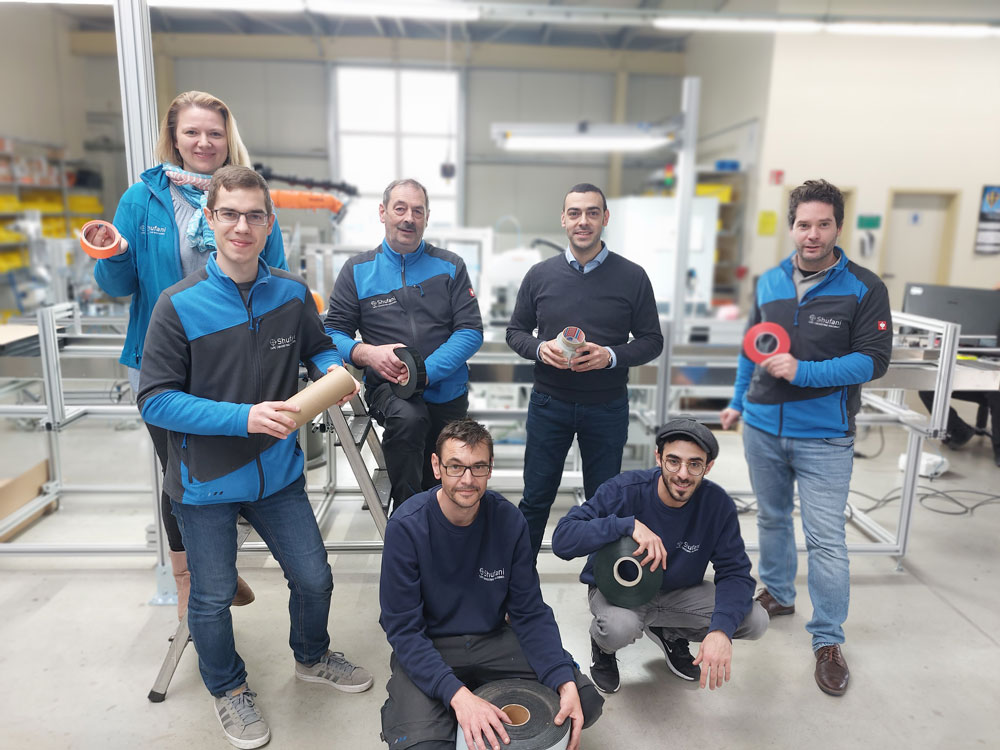

As an innovative, owner-managed company with a team of 20 people, we work flexibly and closely together to provide our customers and partners with the best possible service. We plan, develop, produce and program our systems in-house, including all the electrical engineering. In addition to our in-house production, we also have a large portfolio of different services.

⟶ ISO certificate (PDF 568.6 kB)Special machine builder

specializing in the adhesive tape industry

For more than fifteen years, Dr. Shufani and J. Khoury and their team have succeeded in picking up on the latest technical developments and supplying machines for the production and die-cutting of adhesive tape and films for every desired requirement profile.

Shufani offers expandable modular systems as well as complete solutions, good service and maximum precision and flexibility in the search for individual solutions.

Career

Become part of our team and work in a future-oriented industry and shape the world of adhesive tape processing and automation technology together with us - we look forward to receiving your application:

Company profile:

Wir sind ein Team von 17 Köpfen und planen, entwickeln, produzieren und programmieren Sondermaschinen für industrielle Klebebänder. Darüber hinaus bieten wir Automatisierungslösungen durch Pick-and-Place- und Robotersysteme an.

We work closely together as a team and everyone knows their competencies and tasks.

You will be responsible for the production of important milled and/or turned parts for our special machines. Every job offers new tasks and challenges because every machine is different.

Your tasks:

- You work independently on one of our 3-, 4- or 5-axis machining centers in our production hall milling and / or turning parts made of steel, non-ferrous metals or stainless steel, aluminum, plastics, etc.

- You program either on the machine or in the CAM program according to the technical drawings from the in-house design department or according to finished

- You set up the machine for this, prepare materials and tools, set it up and measure if necessary.

- You finish-machine the parts, deburr them and reliably carry out quality control (according to a test plan or on your own initiative).

- You document your results and

- Even though all of our systems have maintenance contracts, you handle the machines with care and take care of maintenance, minor servicing work and prepare the machine for maintenance.

What you should bring with you:

- You can operate CNC machines safely and have relevant experience and / or appropriate training.

- You can confidently handle CNC controls from Siemens / Heidenhain, or have extensive CNC experience with other controls and are willing to learn programming with both systems with us.

- You are familiar with measuring equipment and presetting devices

It would be nice if you could do that too:

- You are familiar with CAM programming or are willing to learn it.

- If you are interested in even greater challenges, it is good if you would like to take on responsibility and can imagine managing production projects in the future.

- You are familiar with the processes and procedures in production.

This is how we work:

- We have a wide variety of backgrounds in terms of training and our skills as a team. We all pull together and are happy to help each other to achieve our goals.

- We optimize our concepts in weekly project meetings. All ideas are heard and discussed here because we want to keep developing.

- This also includes standardizing our processes and structuring ourselves even better without losing flexibility for our customers.

- In summer and winter alike, we like to fire up the barbecue and have lunch together.

- The management is really committed to its employees.

This is what we offer you:

- a full-time position with 40h/week.

- 26 vacation days

- Depending on your experience and qualifications, we will pay you an appropriate annual salary.

- Travel allowance for the journey to work

- Company pension scheme

- We have a fitness room for use during breaks and after work.

- We support you in your personal and professional development.

- Of course you get coffee, tea and water

Contact person:

Vanessa Ryl

Email: v.ryl@shufani.de

Phone: 033398 254010

Application process:

After checking your documents, we will invite you to a personal interview.

You will get to know the management and colleagues.

Call for applications:

Please send us your CV to v.ryl@shufani.de

Company headquarters:

Dr. Shufani GmbH & Co.KG

Tape Converting Machines

Akazienstr. 7

16356 Werneuchen, Seefeld

Phone: +49 (0) 33398 254010

Company profile:

Wir sind ein Team von 17 Köpfen und planen, entwickeln, produzieren und programmieren Sondermaschinen für industrielle Klebebänder. Darüber hinaus bieten wir Automatisierungslösungen durch Pick-and-Place- und Robotersysteme an.

We work closely together as a team and everyone knows their competencies and tasks.

You will be responsible for programming our special machines in the project. Every job offers new tasks and challenges because every machine is different.

Your tasks:

- You will program the customer-specific machines in our workshop. We prefer to use the control system (PLC) from BoschRexroth / Siemens, Codesys

- You write the machine documentation and operating instructions for our customers.

- You will commission the machines at the customer's site (throughout Germany) and test the connected devices and signals.

- You provide technical support for our customers and always find a suitable solution for machine malfunctions (support mostly by phone/online, sometimes on site).

Another task in the project is the creation of circuit diagrams, which you can also take on or learn.

- You create the circuit diagrams in EPLAN and coordinate with the project team for subsequent project work, e.g. purchasing parts.

- Together with your colleagues from assembly, wiring control cabinets and machines is part of your job.

What you should bring with you:

- You have basic experience with PLCs.

- You are familiar with commissioning machines and testing functions, connections and signals.

- You have a class B driver's license.

It would be nice if you could do that too:

- You can write the operating instructions for our customers in German and we speak German with each other in the team.

- We look forward to your ideas for projects, improvements and suggestions for solving technical problems.

This is how we work:

- We have a wide variety of backgrounds in terms of training and our skills as a team. We all pull together and are happy to help each other to achieve our goals.

- We optimize our concepts in weekly project meetings. All ideas are heard and discussed here because we want to keep developing.

- This also includes standardizing our processes and structuring ourselves even better without losing flexibility for our customers.

- In summer and winter alike, we like to fire up the barbecue and have lunch together.

- The management is really committed to its employees.

This is what we offer you:

- a full-time position with 40h/week.

- 26 vacation days

- Depending on your experience and qualifications, we will pay you an appropriate annual salary.

- Travel allowance for the journey to work

- We provide a car for trips to the customer.

- Company pension scheme

- We have a fitness room for use during breaks and after work.

- We support you in your personal and professional development.

- Of course you get coffee, tea and water

Contact person:

Vanessa Ryl

Email: v.ryl@shufani.de

Phone: 033398 254010

Application process:

After checking your documents, we will invite you to a personal interview.

You will get to know the management and colleagues.

Call for applications:

Please send us your CV to v.ryl@shufani.de

Company headquarters:

Dr. Shufani GmbH & Co.KG

Tape Converting Machines

Akazienstr. 7

16356 Werneuchen, Seefeld

Phone: +49 (0) 33398 254010

Company profile:

Wir sind ein Team von 17 Köpfen und planen, entwickeln, produzieren und programmieren Sondermaschinen für industrielle Klebebänder. Darüber hinaus bieten wir Automatisierungslösungen durch Pick-and-Place- und Robotersysteme an.

We work closely together as a team and everyone knows their competencies and tasks.

In the project, you are responsible for assembly and various tasks in the workshop. Every job offers new tasks and challenges because every machine is different.

Your tasks:

- You saw, drill and process aluminum profiles according to drawings.

- You assemble the assemblies of the machines according to specifications.

- You keep an eye on stock levels.

- You assemble the machines and are involved in deliveries

- You will travel with us to maintenance and repair jobs to our customers in Germany and can later carry them out on your own.

- You support colleagues and customers with troubleshooting and fault rectification.

Another task in the project is assisting with the installation of electronic components, which you can also take on or learn with us.

- You assemble electronic and pneumatic components (e.g. motors, valves) according to specifications.

- Powder coating and painting of sheet metal

What you should bring with you:

- You have basic experience in mechanics and the assembly of systems in industry.

- You work precisely and cleanly according to drawings.

- You have a class B driver's license.

It would be nice if you could do that too:

- You have experience of working on conventional lathes and milling machines.

- You can create and edit maintenance reports and other necessary documentation in German using MS Office.

- We look forward to your ideas for projects, improvements and suggestions for solving technical problems.

This is how we work:

- We have a wide variety of backgrounds in terms of training and our skills as a team. We all pull together and are happy to help each other to achieve our goals.

- We optimize our concepts in weekly project meetings. All ideas are heard and discussed here because we want to keep developing.

- This also includes standardizing our processes and structuring ourselves even better without losing flexibility for our customers.

- In summer and winter alike, we like to fire up the barbecue and have lunch together.

- The management is really committed to its employees.

This is what we offer you:

- a full-time position with 40h/week.

- 26 vacation days

- Depending on your experience and qualifications, we will pay you an appropriate annual salary.

- Travel allowance for the journey to work

- We provide a car for trips to the customer.

- Company pension scheme

- We have a fitness room for use during breaks and after work.

- We support you in your personal and professional development.

- Of course you get coffee, tea and water

Contact person:

Vanessa Ryl

Email: v.ryl@shufani.de

Phone: 033398 254010

Application process:

After checking your documents, we will invite you to a personal interview.

You will get to know the management and colleagues.

Call for applications:

Please send us your CV to v.ryl@shufani.de

Company headquarters:

Dr. Shufani GmbH & Co.KG

Tape Converting Machines

Akazienstr. 7

16356 Werneuchen, Seefeld

Phone: +49 (0) 33398 254010

Industries –

Market for our products

Industrial adhesive tape is used in a variety of applications to hold or fasten objects together. There is a wide range of industrial adhesive tapes with different properties to meet the specific requirements of different applications.

What is industrial adhesive tape

Adhesive tape is one of the most exciting joining technologies of the future and is used in almost every industry.

Adhesives are applied to a carrier material and then further processed depending on the application. By combining different materials, certain properties can be added to the adhesive tape, such as protection against environmental influences, scratches, vibration and also insulation against heat, moisture and electricity.

In principle, almost all materials can nowadays be made self-adhesive and brought into the required shape. Adhesive tape is therefore not only used to join individual parts and assemblies, but also solves complex problems in manufacturing, assembly and fastening technology and functional films can be used to perfectly protect surfaces.

Adhesive tape and corresponding die-cut parts offer many advantages over conventional mechanical joining techniques such as screws, rivets, nails, etc., particularly in terms of weight, accuracy, speed, space saving, appearance, safety, addition of properties and process optimization.

We will be happy to advise you on whether adhesive tape is the right solution for your product design, because the earlier the right joining technology is taken into account in the entire production process, the more efficient the overall solution will be, especially for larger quantities or complex assemblies where tolerances play a role.

Our batch sizes start at just 1, and we work closely with leading adhesive tape manufacturers and converters.

Get in touch with us →Industrial adhesive tape can be found in the following sectors in particular:

Automotive and transportation

Aerospace technology

Electronics, displays and batteries

Household appliances / white goods

Healthcare, medical technology, hygiene articles

Construction industry

Renewable energy

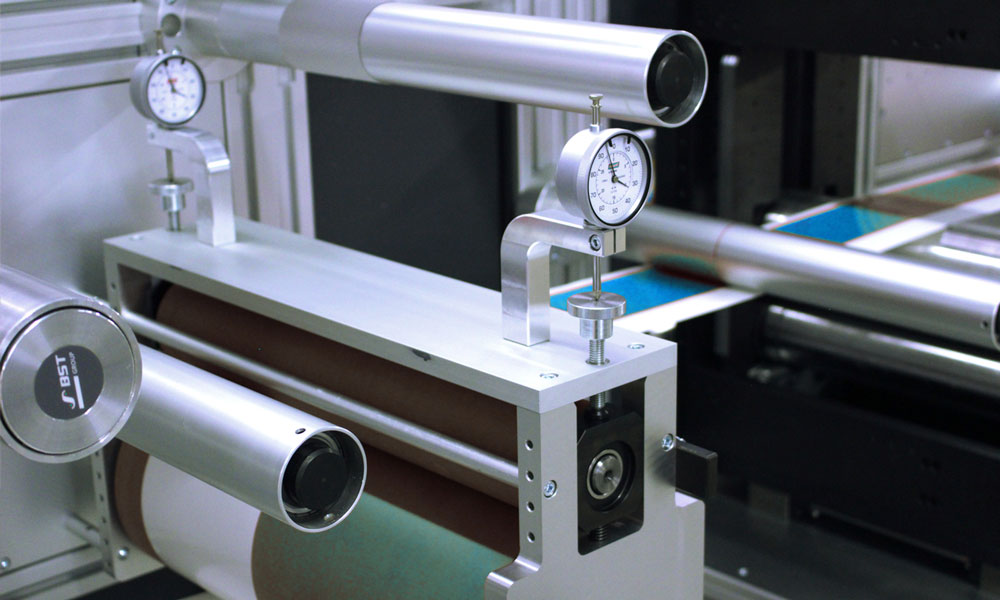

What is a converter or converting?

Adhesive tape is usually produced in large rolls on huge coating lines. These so-called jumbo rolls or logs are then rewound to a specific length and cut or slitted to the corresponding width. This produces smaller rolls for better handling. These are then further processed on plotters, flatbed die-cutters or rotary die-cutters and cut to a specific shape. This can be done using mechanical cutting processes, lasers, ultrasonic or water jets.

As a rule, rotary processes are significantly faster and produce roll goods that are easier to process in automated processes or attach to components. In addition, new layers of material can be added or changed by laminating and the end product can be individualized and adapted precisely to your needs.

A converter has an extensive range of machinery at its disposal to professionally handle precisely these work steps for you. The process itself is called converting, as in the textile industry.

What is automation

In the modern production environment, the automation of processes and workflows is playing an increasingly important role. An automation solution can already be worthwhile for smaller quantities and is not only useful for larger production volumes. One of the main advantages lies in the process reliability achieved through automation. Consistent production quality, i.e. repeatability, is achieved, usually with greater efficiency and less effort. This frees up resources and allows you to become an even more reliable supplier.

A great deal of experience and precision is required, especially when it comes to processing and applying adhesive tape and films. Maintaining tolerances and applying components without wrinkles or bubbles, as well as preparing the surface to be taped accordingly, require additional know-how beyond classic automation technology. After all, anyone who has ever worked with adhesive tape knows how complex this material can be. It often sticks all too readily in the process exactly where it should not.

We also offer you suitable automation solutions for packaging, sorting and stacking. Our services also include the integration of automated quality controls, e.g. error detection, marking or sorting and re-sorting. In the area of assembly, we can easily implement component recognition, removal and placement for you using state-of-the-art robot technology, pick & place systems and individually programmed software modules.

We are happy to support and advise you in this area.

Together with you, we look at your production steps through to the entire production process to find out where an automation solution makes sense and is profitable.

Get in touch with us →Related products: Roll goods are not only processed with adhesive tapes, but also in the paper and print sector in particular and, thanks to new technologies such as ultrasonic or laser welding and cutting, also in the medical and hygiene sector. Frequently processed materials include

- Adhesive tape

- Textiles, microfiber, nonwovens

- Foams and sealants

- Slides

- RFID sensor applications and printed electronics

- Aluminum strips

- Paper and labels

Nowadays, a wide range of materials and components can be "self-adhesively" fitted and wound onto rolls.