Support: If, after consultation with our technicians, remote access to your system is necessary, please follow the link to download and set up the connection using TeamviewerQS.

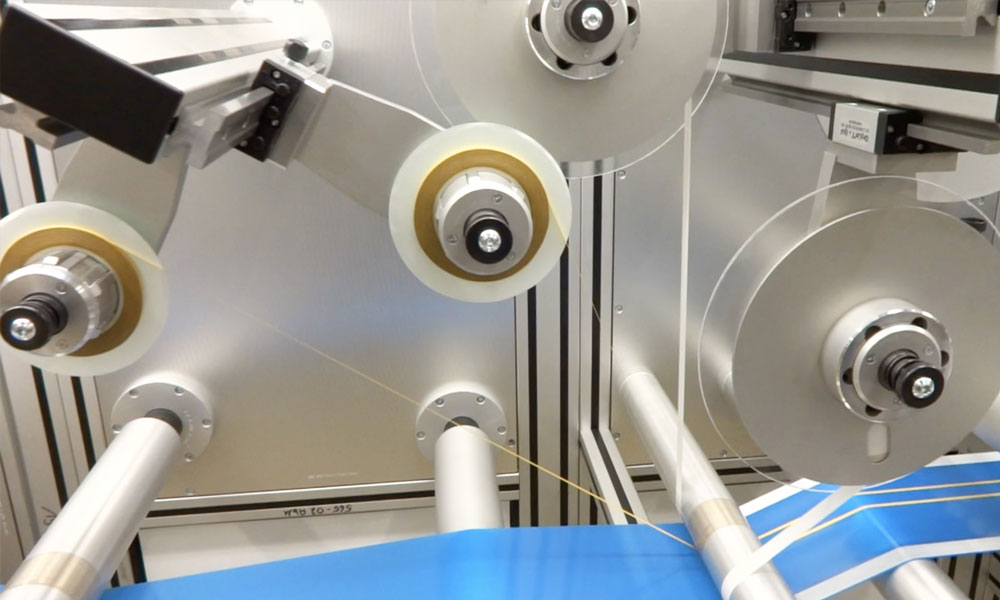

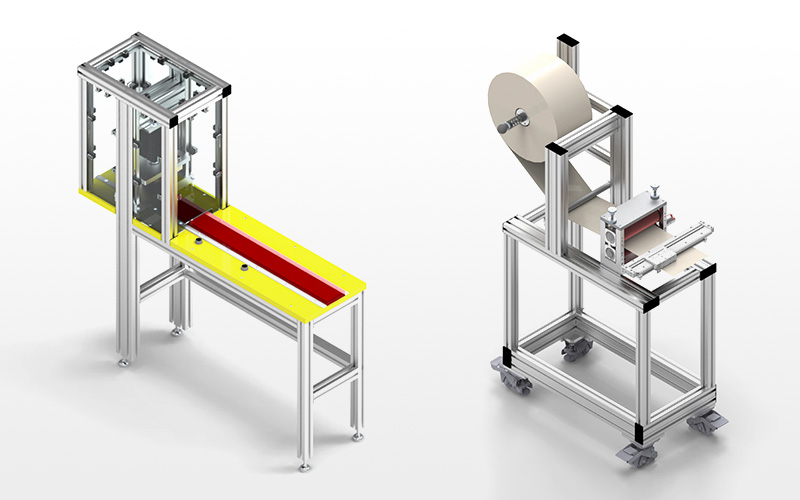

Special machine construction

for the adhesive tape industry

Everything you need for processing and applying adhesive tape and similar materials such as films, foams and textiles. Customized automation solutions.

Dr. Shufani and its team have significantly advanced the development of cutting and punching processes and set new standards. However, we do not stop after cutting and punching, but serve the next step in the process chain with a wide range of applications and help you to attach your punched parts or protective foils to the components and assemblies, manually, semi-automatically or fully automatically. To round off the process chain, we also offer individual special solutions for your automation requirements.

We always use the latest technologies to achieve a unique combination of performance, flexibility and accuracy. In addition, all our solutions are modular in design and can be expanded at any time. This means they can always keep pace with the latest trends and requirements.

Tailor-made solutions are developed in constant coordination with customers, partners and suppliers. Clear menu navigation and software modules ensure that the systems are easy to operate and allow complex parameters to be precisely matched to a wide variety of materials and orders.

Our systems and equipment help you to convert your adhesive tape and films to the right length, width and shape. We have the right solution for you to produce as accurately and efficiently as possible and deliver reliable, repeatable results according to your needs and monitor them as required.

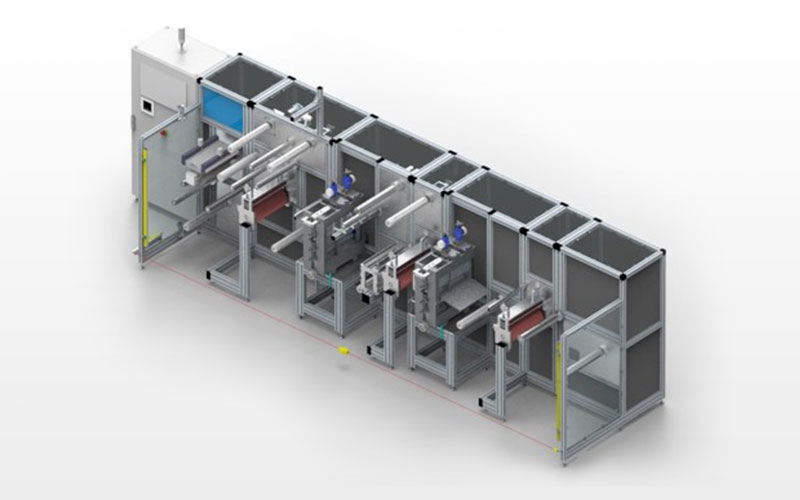

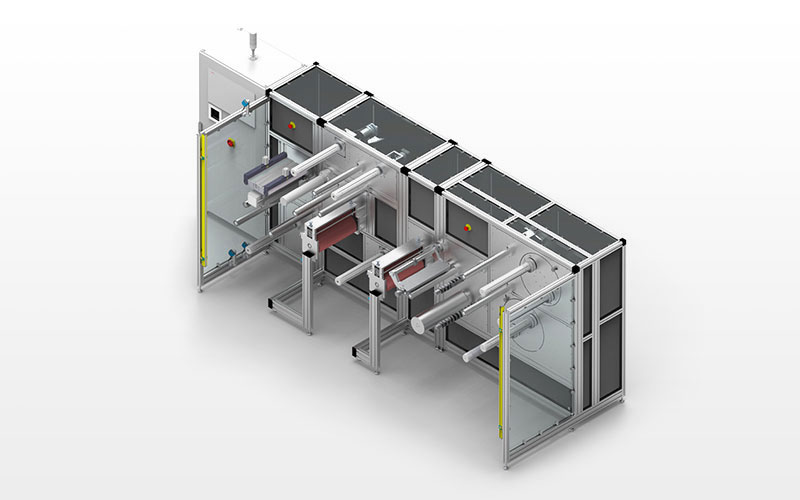

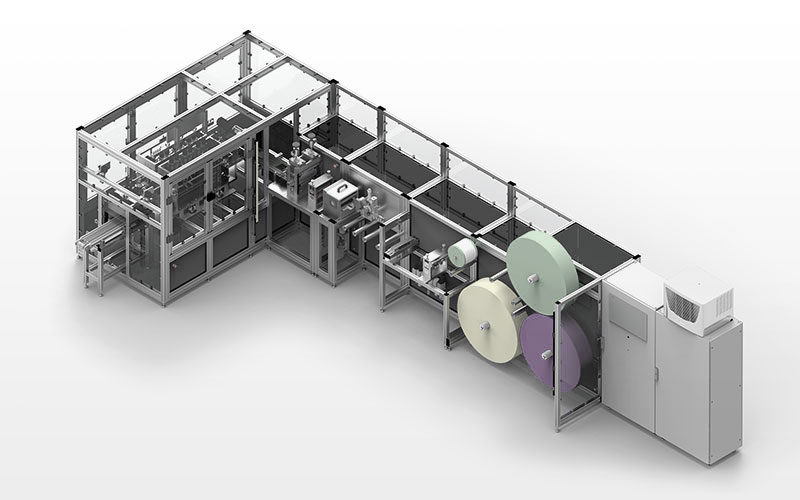

Modular rotary die-cutters

- Flexible module combination, expandable at any time

- Individually driven axes (servomotors)

- Standard working widths 200 / 400 / 600

- Multiple die-cut units possible, register control, crosscut, laminating

- Extensive range of accessories: pulling station, lifter, mobile shafts, web edge control, integrated quality control

Slitting machines V 30 / V 31, roll cutters:

- Fully automatic cutting programs and cutting parameters that can be individually adjusted to materials and jobs

- Separator function, scanning function, automatic cutting, quick knife change at the touch of a button

- Cutting width from 0.2 mm

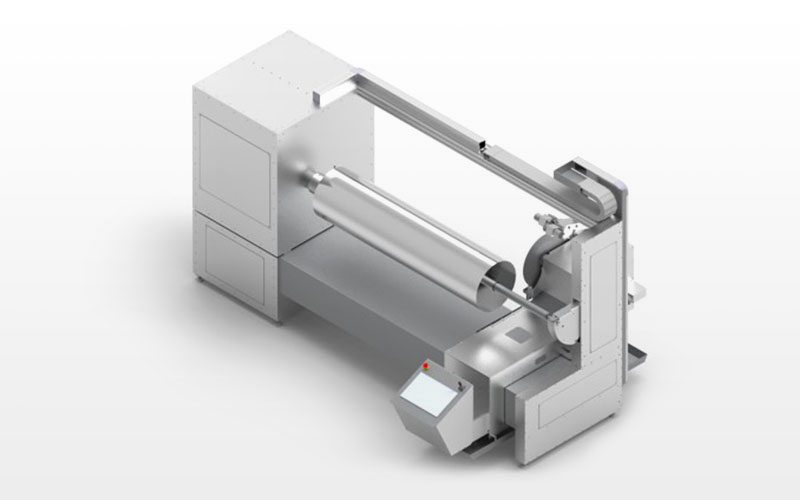

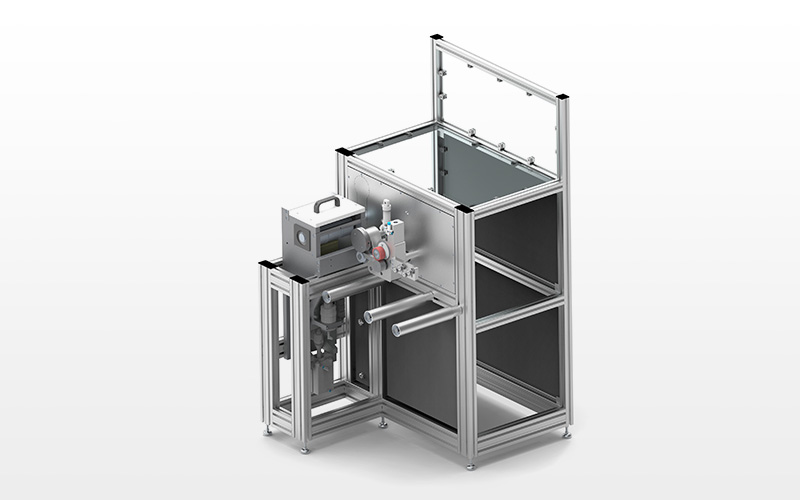

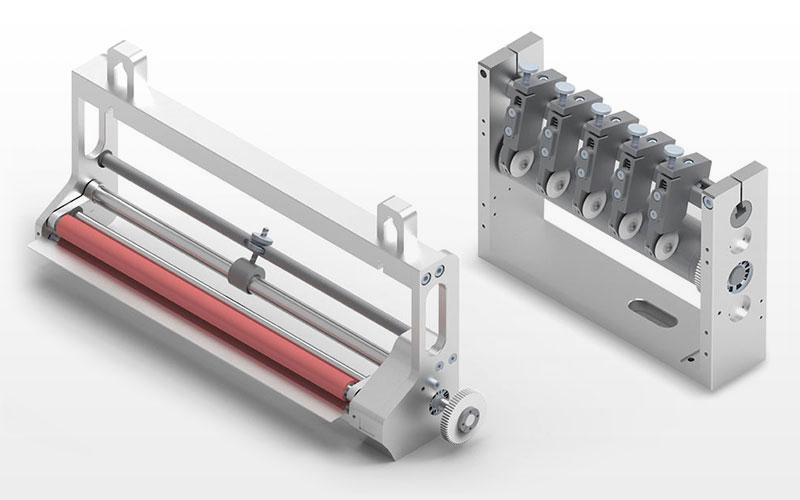

Rewinder and slitter-rewinder

- Compact rewinder for web widths up to 200 mm

- Production of short rolls, coreless winding

- Optionally with cutting unit

- From 1-6 inch, adaptable, quick-change system

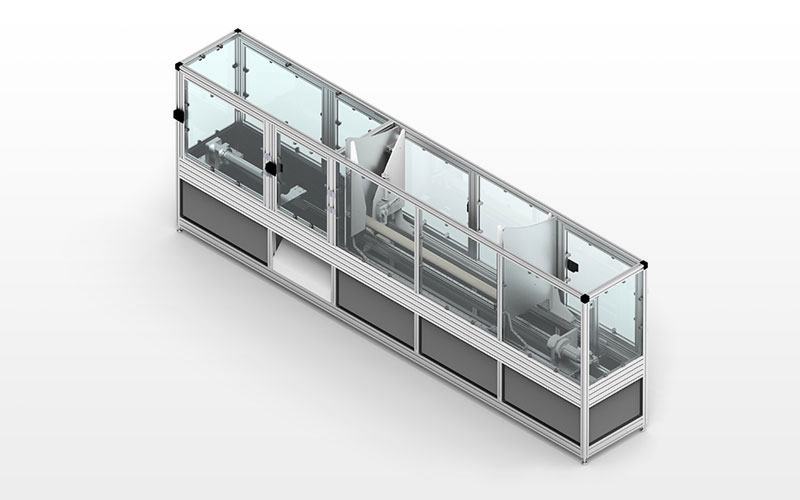

Rewinding slitter with turning disks

- All standard cutting options: Longitudinal cut (crush cut, shear cut, blade cut)

- Turning disks with 4 axles, guide shafts

- Easily exchangeable expansion shafts 1-6 inch, optional friction shafts

Cutting and welding solutions: with laser or ultrasonic

- Ultrasonic: Simultaneous cutting and welding of edges for textiles, microfiber, nonwovens, foams, etc.

- Laser: cutting / punching, marking, engraving and labeling

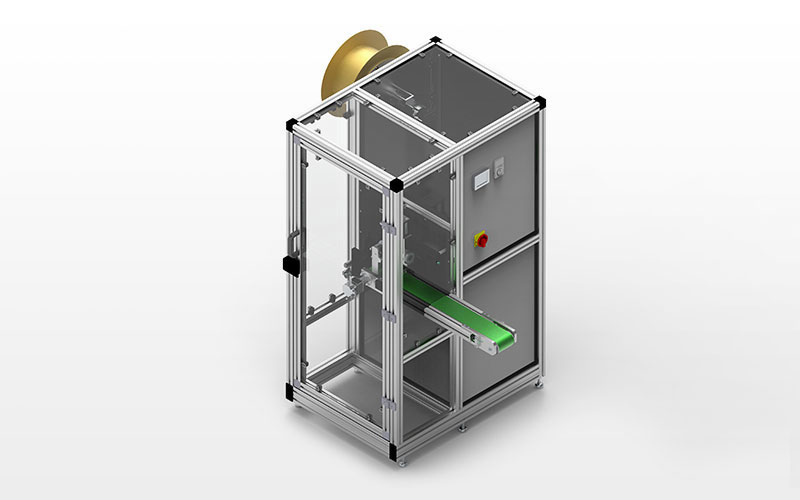

Core cutter

- Semi-automatic with manual loading

- Fully automatic with magazine, core length up to 2m

- 1-6 inch cores

- Optionally with integrated sorting and conveyor belt

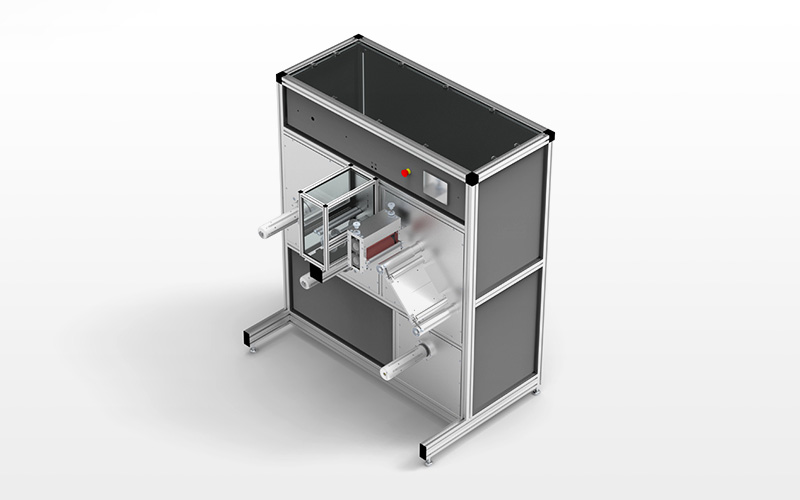

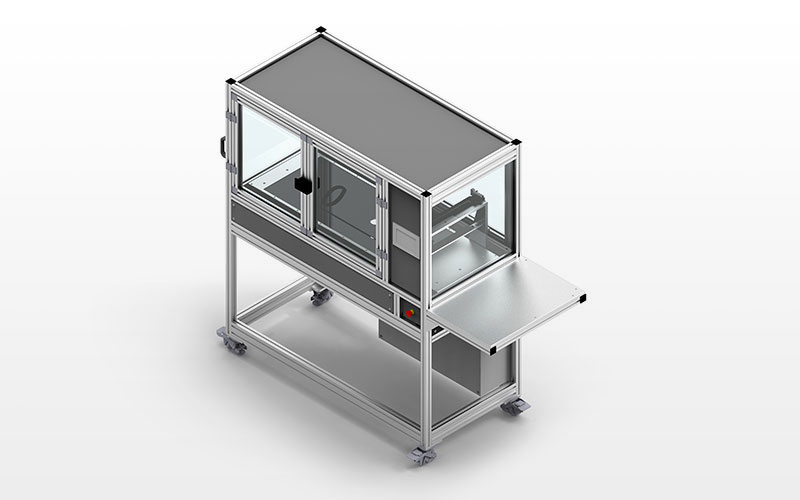

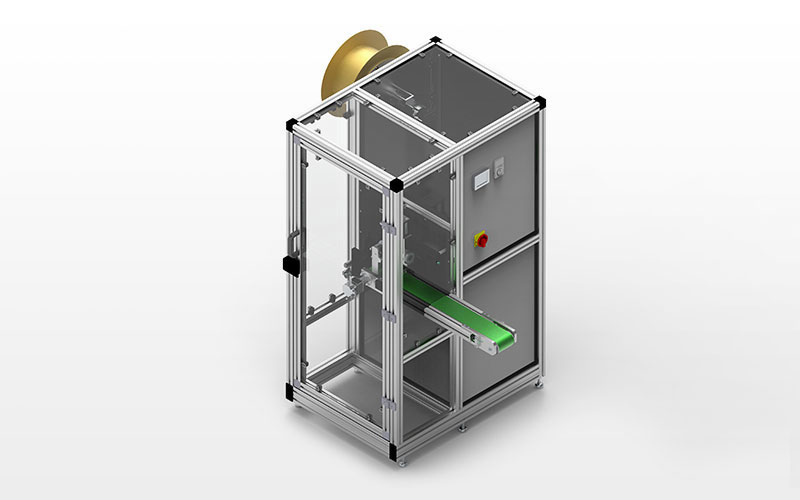

Automatic “cut-to-length machines”

- Free-standing machine for unwinding and cutting to length, e.g. cross-wound materials

- Creation of pull-tabs by scraping

- Optionally with conveyor belt or slide

- Also suitable for foams

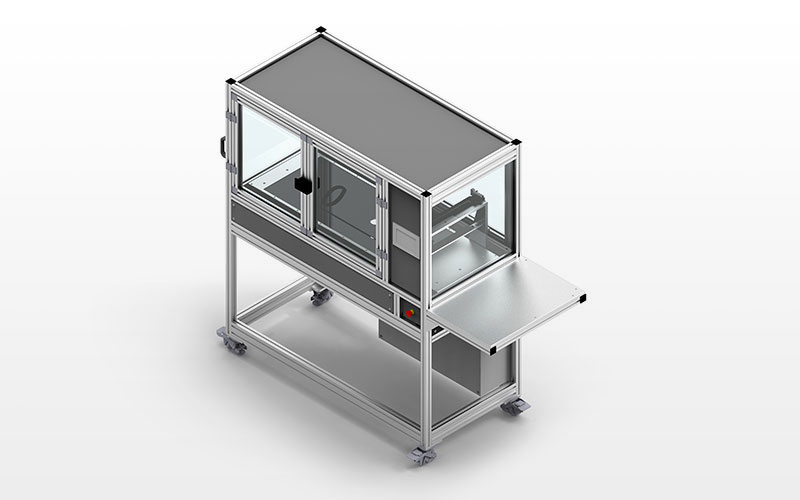

Measuring tables and measuring systems for quality control

- Non-contact measurement of punching parts and components (2D)

- Large measuring range: 400 x 1000mm

- Precession line scan camera system (Keyence)

- Electrically driven linear axes

Accessories

- Extensive range of accessories for our modular systems:

- Scoring tool, pulling station, lifter, folding station, blow-out station, web edge control, measuring rollers and sensors, mobile shafts, guide shafts, support discs, splice function, controlled sockets, ionization solutions

- Tool lifter and tool handling

- Remote Control

- Slides, conveyor belts, stacking modules and feeding stations (loading)

- Mountings

Do you want to attach your punch or die-cut parts or protective films to components or assemblies? We have the right solution for you, manual, semi-automatic or fully automatic, depending on the quantities. Bubble and crease-free, complex geometries - no problem, we will work with you to find the right device.

Manual

- Application device for roll goods

- Linear and profile applicators

- Toggle presses

- Variable receptacles (vacuum)

- Mobile, free-standing or table versions

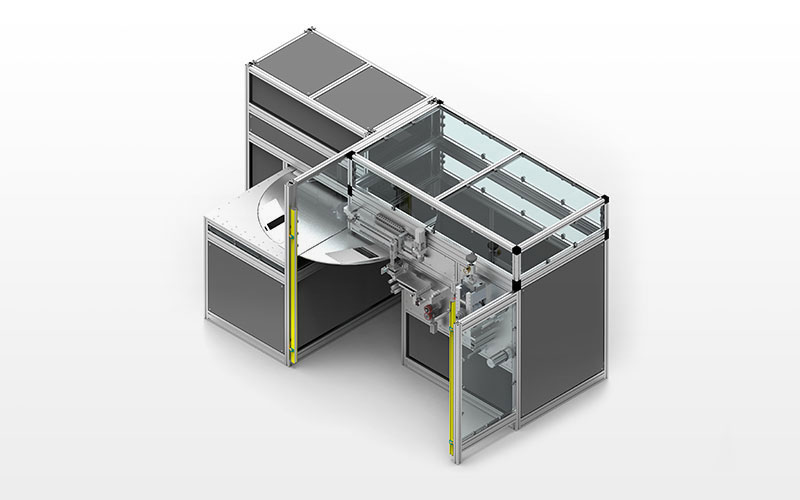

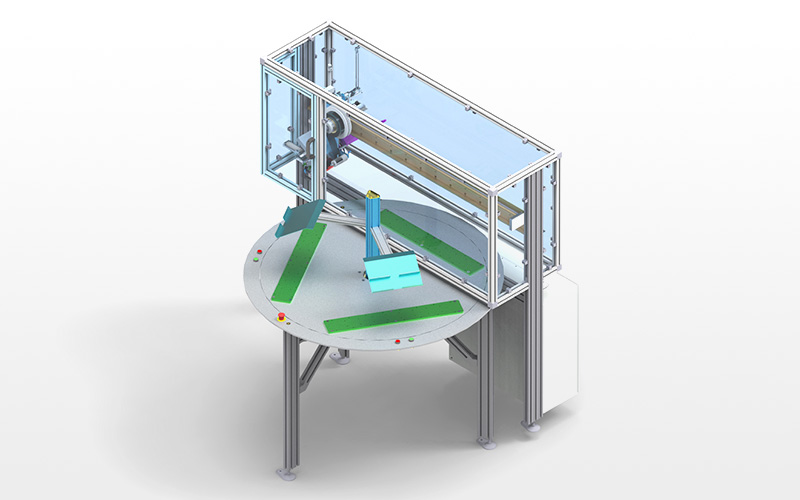

Semi-automatic:

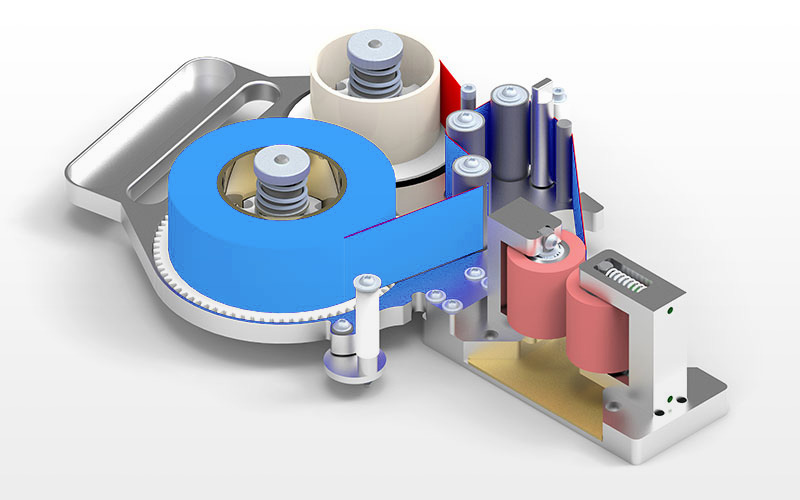

- Semi-automated workstations with rotary indexing table, manual component placement, automatic application

- Dispensing machines

- Linear and profile applicators for (decorative) strips, panels, trims and profiles

- Optionally with integrated pull test and quality control

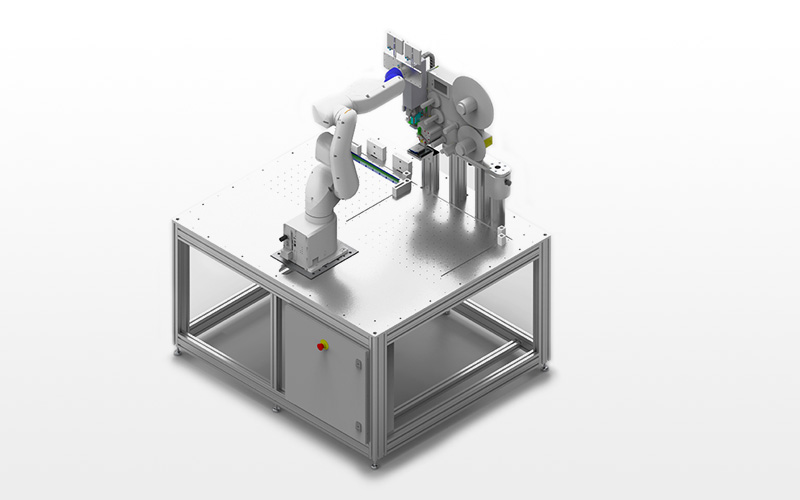

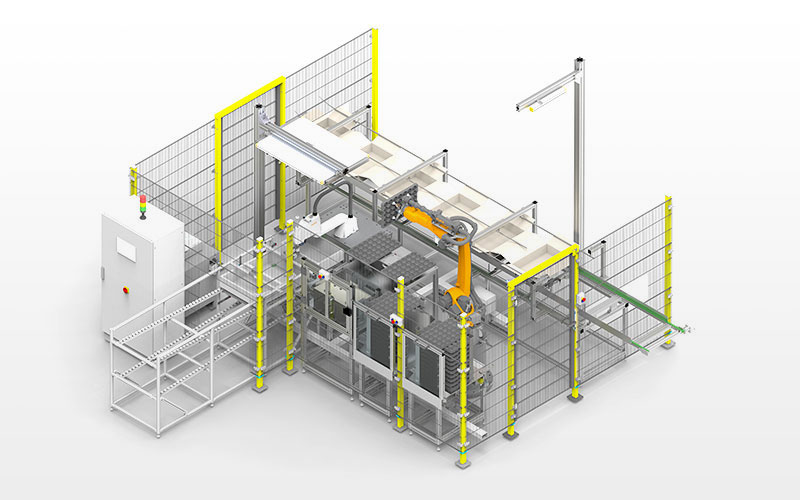

Fully automatic:

- Robotic solution for the fully automatic application of e.g. pull-tabs or die-cut parts to components and assemblies

- Fully automated workstations with rotary indexing table and robot loading (optionally with integrated pull test and quality control)

- Complete "application lines" with rotary indexing table, robot loading and conveyor belts

Hand applicator

- Installation variant for stationary taping of profiles and strips

- Manual handling for taping

- Integrated liner rewinder

- Unwinding from the roll or cross-wound material

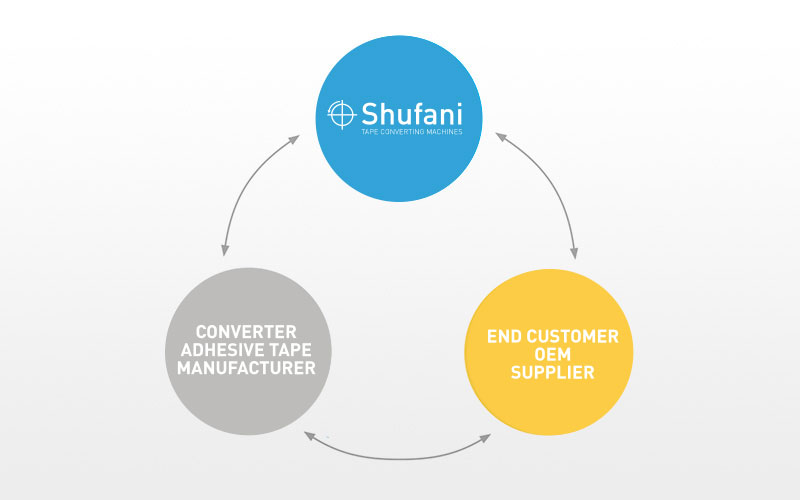

Connection between adhesive tape manufacturer - converter - end customer:

- We are happy to be the extended arm for converters and adhesive tape manufacturers and work with them to offer A-Z solutions for end customers (OEMs, T1, T2, T3) for processing and applying different materials.

We are very practice-oriented

and always think in terms of our customers.

That is why we build our systems to be modular and expandable.

Automation solutions

- Positioning and repackaging (boxes, trays, cartons)

- Optical detection and control

- Pick & Place

- Stacking, portioning, storing, sorting and transferring

Mobile or tabletop “cut-to-length machines” for different materials

- Free-standing machine for unwinding and cutting to length, e.g. cross-wound materials

- Creation of pull-tabs by scraping

- Optionally with conveyor belt or slide

- Also suitable for foams

Measuring tables and measuring systems for quality control

- Non-contact measurement of punching parts and components (2D)

- Large measuring range: 400 x 1000mm

- Precession line scan camera system (Keyence)

- Electrically driven linear axes

Rotary indexing tables

- Assembly rotary indexing table

- 2 manual stations, 1 fully automatic station

- Pressing or bonding of components

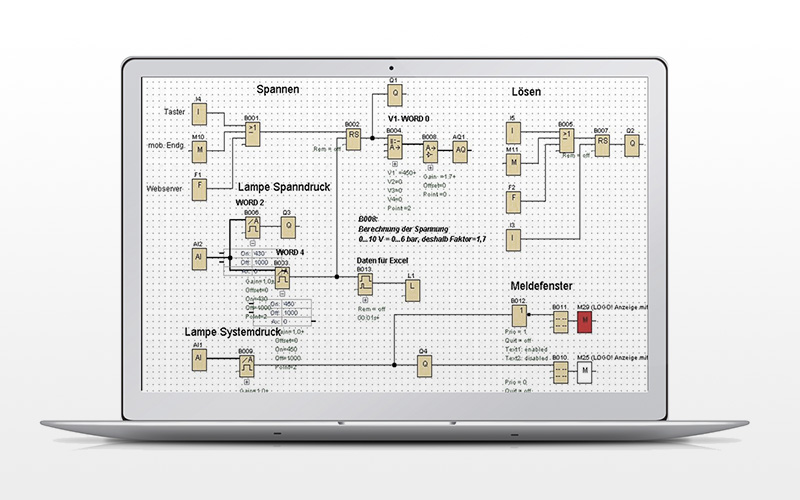

Software module components

- Modules for converting machines: register control, cross-cut, separator function, scanning, quality control, data management, etc.

- System integration

- Optimization and expansion, software updates, remote maintenance

- Production: Set up of products and orders (system training)

Mask machines and special solutions

- Medical and FFP2 masks

- Ultrasonic welding and flow processing

- Packaging

*** Discontinued model - production stop

Miscellaneous

- Lifting punch for foams, sanding foams and hard materials

- Paper / roll cutter